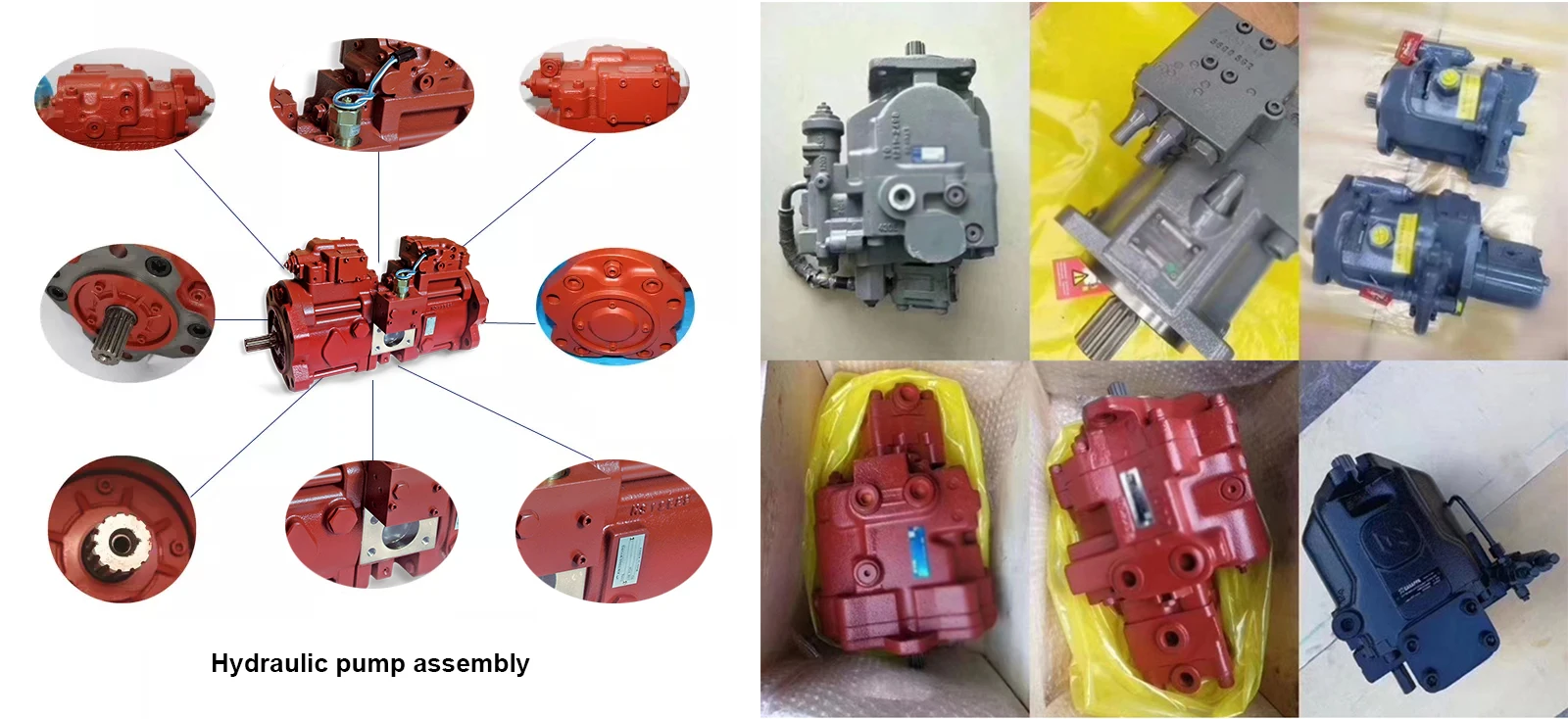

Excavator Hydraulic Pump Maintenance Information

페이지 정보

본문

We should always regularly test and maintain the Excavator hydraulic pump. Commonly examine the hydraulic pump and its surrounding connecting elements and seals to make sure there aren't any leaks or wear. Test the operating strain and move rate of the hydraulic pump to make sure it's within the normal vary. Usually test the cooling system of the hydraulic pump to keep the temperature within the appropriate range. Piston pumps may be operated with or without a stress-regulating machine. They're self-priming and don't require any suction lift or suction head, making them uniquely suitable for many applications. Though they have been used as commonplace hydraulic elements in excavators since the beginning, they nonetheless have some advantages that have become extra necessary over time. Nothing equals the impression drive of hydraulic breakers. With the very best energy-to-weight ratio, higher blow vitality, and lower noise stage than pneumatic breakers, Stanley hydraulic breakers are merely the only option. Our 70-lb. class breakers ship roughly the same impact vitality as most 90-lb. pneumatic breakers. Inner components are continually bathed in hydraulic oil, offering lengthy tool life with minimal upkeep. For the reason that hydraulic system is completely enclosed, there is no such thing as a software exhaust or oil atomization.

This versatile and powerful machine might be tailored for any job and is suitable for a wide range of functions. Give your job site a lift and achieve fast outcomes. Increased energy to 58 hp (forty three.3kW) and improved cooling guarantee optimized efficiency in any climate. For the ultimate mixture of energy and efficiency, the engine helps to push by challenging situations. It doesn’t matter if you are a veteran technician or a contractor who desires to study extra about the basics; this article ought to provide you with what it takes to ensure your excavator’s hydraulic system works greatest. What Are the main Parts of an Excavator Hydraulic Pump? An excavator hydraulic pump comprises numerous necessary parts in remodeling mechanical energy into hydraulic energy.

Apa itu K3V hydraulic pump Breaker Excavator? Hydraulic breaker atau breaker merupakan peralatan yang umum dan ekonomis dalam pekerjaan penghancuran (demolition) pada proyek konstruksi, pertambangan, atau quarry. Peralatan ini dipasang sebagai attachment pada alat berat seperti excavator atau skid steer loader, memerlukan pengoperasian yang tepat untuk memastikan daya tahan yang optimal. Dengan tenaga besar, hydraulic breaker menjadi mesin produktif yang sangat berguna dalam pengerjaan jalan beton atau aspal, penghancuran pondasi beton, dan pemecahan batu yang mungkin ditemukan selama pekerjaan. By fastidiously evaluating these factors, you may select the suitable size of hydraulic breaker that may maximize effectivity and effectiveness in your undertaking. Hydraulic breakers are powerful tools utilized in numerous demolition and excavation duties. They are designed to interrupt through powerful materials resembling concrete, rock, and asphalt. However, choosing the right dimension of hydraulic breaker for your undertaking is essential to ensure optimum efficiency and effectivity. Understanding the principle components of an excavator is crucial for anybody concerned in the development or industrial sectors. Each component, from the undercarriage that provides stability and mobility, to the hydraulic system that powers the machine’s movements, plays an important function in making certain the excavator operates efficiently and successfully. If you’re in the market for excavator elements, or if you’re wanting to reinforce your machine’s capabilities with new attachments, our stock has everything you want. We offer a wide range of high-high quality parts and equipment designed to keep your excavator operating smoothly and efficiently, no matter the job.

Sensible Pump Expertise: Smart pump know-how integrates advanced sensors and clever algorithms to optimize pump performance. These pumps constantly monitor operating situations, resembling load, temperature, and strain, and make actual-time adjustments to make sure optimum effectivity and reliability. Smart pump technology enhances the overall performance of the hydraulic system, reduces energy consumption, and improves tools longevity. Hybrid Methods: The integration of hydraulic and electric systems has led to the event of hybrid excavators. Hybrid programs mix hydraulic pumps with electric motors and batteries, enabling power regeneration and storage. Totally different methods are employed on various breaker sizes and brands. A lot of techniques make the most of a hose that runs from the provider to use constant lubrication to the breaker. Some manufacturers produce breakers that come normal with a lubrication cartridge mounted straight onto the breaker itself. With this system, actually all that's required of the operator is to alter the tube when it is empty.

Hydraulic breakers, also referred to as rock breakers or hammers, are sturdy attachments fitted to excavators or different heavy equipment. They make the most of hydraulic power to ship high-affect blows to interrupt and fragment laborious materials like rocks and concrete. In mining, hydraulic breakers are important for duties such as tunnelling, quarrying, and ore extraction, the place exact and environment friendly rock fragmentation is essential for productivity and security. The rising demand for metals and minerals globally has spurred mining actions, consequently driving the demand for hydraulic breakers. The piston fires into the shank, but the power is not taken into something, resulting in the shock despatched again into the device and clashing with different shocks. This ends in undue wear and tear on the breaker. Having an experienced operator can sense a break and cease the instrument to limit the amount of blank fires as it's getting used. As with all your tools, a hydraulic breaker have to be inspected before you use it to make sure secure operation. Test that it is greased and lubed up, and examine for worn parts and free fittings.

- 이전글Volvo Development Equipment 24.10.18

- 다음글Ein Immobilienkredit ist eine spezielle Form des Darlehens, das zur Finanzierung von Immobilienkäufen, -bauten oder -sanierungen verwendet wird. 24.10.18

댓글목록

등록된 댓글이 없습니다.